Download our Cathodic Protection Cable Infographic!

To understand Cathodic Protection Cable (CPC), it is first helpful to understand what Cathodic Protection (CP) is. CP is a way to prevent corrosion of metal. This system utilizes a sacrificial anode connected to what you are trying to protect via a cable.

For example, all gas and oil pipelines, water heaters, ship hulls, and wind farm foundations would have cathodic protection systems to protect from corrosion.

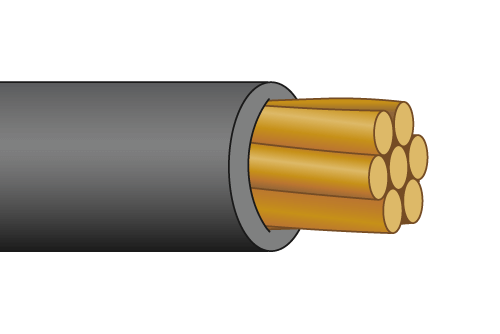

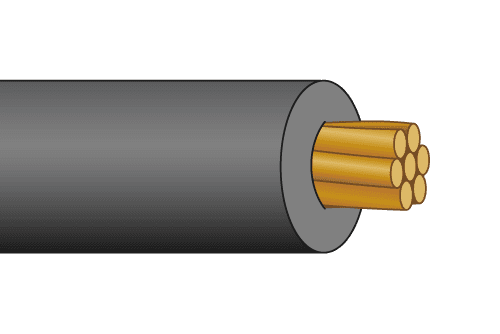

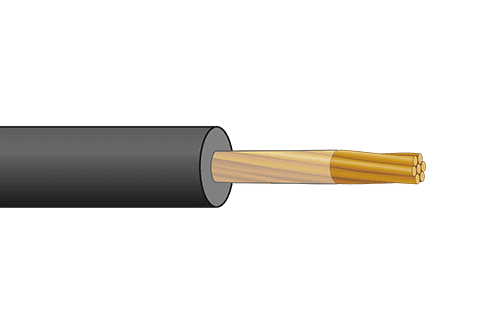

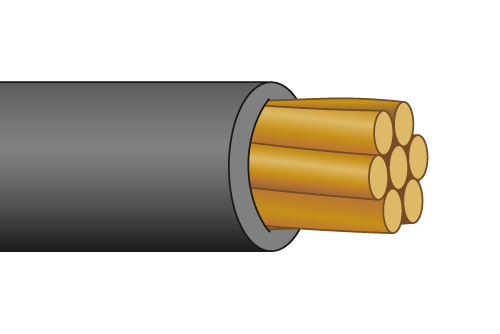

Cathodic Protection Cable consists of a copper conductor insulated with a plastic compound that is highly corrosion and abrasion resistant.

Equipped with either a High Molecular Weight Polyethlene (HMWPE), Halar (ECTFE), or Kynar (PVDF) jacket, cathodic protection cable is typically a stranded construction. It is designed for usage in places where there is moisture or corrosive chemicals such as chlorine gas (namely salt or brackish water).

Though the HMWPE, Halar, and Kynar jackets are thick, an advantage of the material is that it is highly flexible, which makes it easy to work with.

Cathodic protection cable is direct burial rated and is suitable up to 600 volt usage. Additionally, the standard black color is naturally sunlight resistant and all colors are available as sunlight resistant upon request.

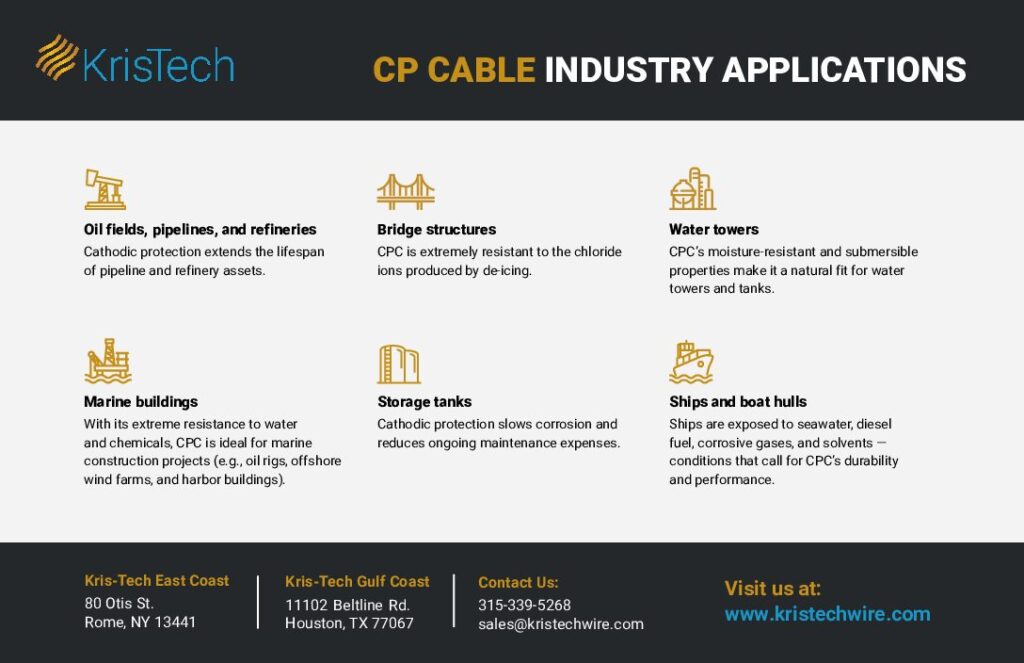

Cathodic protection cable is ideal for any industry where it is imperative to protect steel from moisture, salt, or chemicals such as:

A primary advantage and fundamental goal of CPC is that it helps reduce the aging of metal building structures.

Industries that are good applications for cathodic protection wire are oil, petroleum, departments of transportation (specifically bridge construction), municipal waterworks, and onshore and offshore marine construction such as piers and pilings.

Essentially, any organization that has construction projects in corrosive environments. For example, an oil and gas company that decides to build an oil rig will require CPC cable. It is also indispensable for oil well casings. Additionally, regions exposed to lots of salt, both coastal and inland, will benefit from cathodic protection.

For the full list of specific technical criteria of cathodic protection, NACE International (National Association of Corrosion Engineers) has a comprehensive report.

Click on the highlighted links to learn more about the product specs and differences between halar, kynar, and hmwpe cathodic protection cable.

Subscribe to the Kris-Tech Blog