By Steve Pietrowksi, National Account Coordinator

If an electrical contractor works in a corrosive environment, then cathodic protection cable is a must.

Cathodic protection cable (CPC) is a specific type of copper wire with a highly protective insulation. While THHN and XHHW have lots of uses in industrial and commercial construction, they are unusable in environments in which copper wire is exposed to corrosive elements. CPC is also NEC approved for submerged construction applications.

There are three types of cathodic protection insulation:

1) High molecular polyethelene (HMWPE)

2) Halar (ECTFE)

3) Kynar (PVDF)

Though the HMWPE and halar coatings are extremely durable the material maintains flexibility to facilitate the installation for electrical contractors. Whether an electrical contractor opts for HMWPE cathodic protection cable or halar/kynar depends on the specific requirements of their job.

Here are 5 common applications for using CPC.

It goes without saying that oil fields are wet and dirty environments. That’s why we see lots of cathodic protection cable orders coming from oil and gas companies that require heavy corrosion and abrasion resistance. When it comes to wire on oil fields, CPC gets the job done.

Whenever a bridge crosses a body of water, whether it’s a river in upstate New York or the Atlantic Ocean when traveling to the Florida Keys, rust and corrosion are a problem. Cathodic protection cable offers protection against chloride ions which is essential for construction over bodies of water.

Regardless of whether the structure is buried or submerged in water, cathodic protection wire ensures longevity against the natural elements that bridge architects, engineers, and electrical contractors face.

Lots of water means lots of opportunities for rust. CPC’s moisture resistance makes it great for applications in water tower construction.

Any type of marine construction, whether for ships, offshore oil rigs, or harbors, requires an ongoing cathodic protection current to protect steel from corrosion. Since cathodic protection cable significantly reduces steel corrosion, it is ideal for marine environments because of all of the seawater which leads to steel damage and rust.

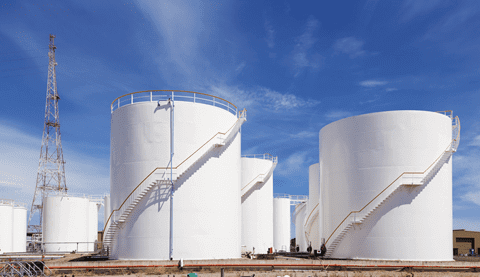

Above ground storage tanks often use cathodic protection. Among the various reasons for using it (along with specific government regulations), less corrosion means less money spent on maintenance expenses.

The corrosion resistance also provides additional environmental protection.

As a cathodic protection cable manufacturer, Kris-Tech Wire produces CPC gauge sizes ranging from #14 to 350 MCM.

To learn more, visit our cathodic protection cable product page.