From natural gas to water and electricity, much of our utility infrastructure is buried underground. Locating these underground assets is critical for maintenance and repairs and avoiding damage or injuries when adding new facilities. Builders and contractors typically use tracer wire (aka locating wire) to find buried pipes and underground structures. Traditionally, solid copper is the established tracer wire of choice. But the alternative, copper clad steel (CCS) wire offers several advantages that make it a compelling option.

Poly tubing is replacing legacy metal piping, and the poly replacements can’t be located with conventional utility locating devices. Instead, tracer wire is buried with the poly tubing. Crews use a frequency generator to send a current through the wire, then pinpoint pipe location by potholing at intervals.

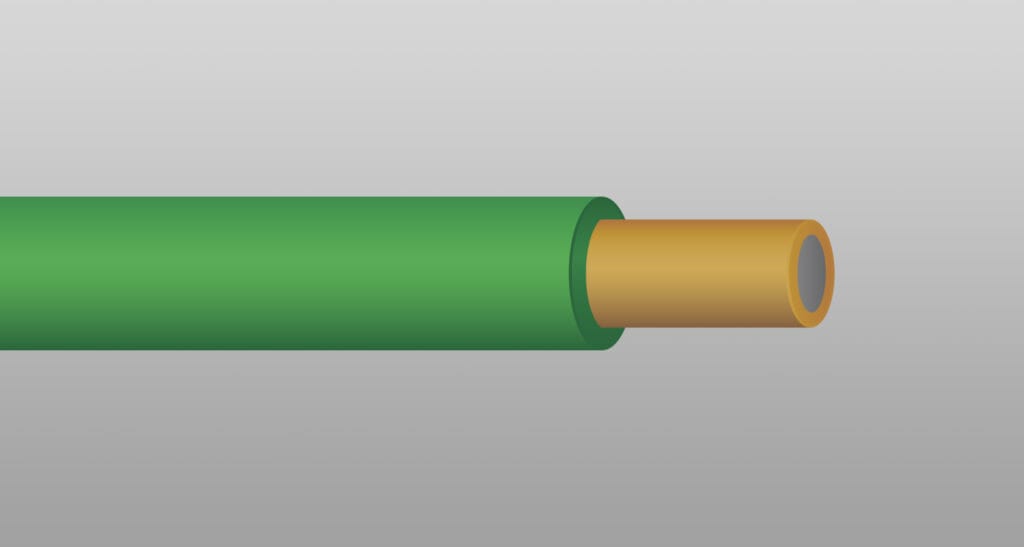

CCS tracer wire is a solid steel core conductor with a concentrically clad copper coating, insulated with a high molecular weight polyethylene (HMWPE). It is suitable for direct burial use in both wet and dry locations

Copper clad steel wire is made by metallurgically bonding solid steel with solid copper. Two copper strips are fixed to a steel rod, then bonded together by pressure and heat. The wire is drawn to an intermediate size and heat-treated, then the process is repeated to achieve the desired wire specification. The heat, pressure, and drawing process ensures that the final product has a consistent copper to steel ratio and a uniform copper cladding.

While solid copper has long been considered the industry standard for tracer wire, the CCS alternative has several benefits that account for its rapidly gaining popularity:

Strength and durability. Traditional copper tracer wire is more flexible and easier to work with than CCS, but it comes with a trade-off. CCS tracer wire has a much higher breaking strength and is more rugged than copper. This ‘pulling strength’ is particularly important when tracer wire is machine-pulled over long distances. For example, in a pipeline application, tracer wire may run for many miles, and breaking a wire is costly in terms of downtime and materials.

Lower risk of theft. Copper has a significant aftermarket value, and over $1 billion of copper is stolen every year. Related damage to infrastructure and replacement labor costs add to the financial toll. By contrast, CCS wire has limited value as scrap and represents a much lower theft risk.

Stable, predictable costs. The price of copper is historically volatile — it has risen over 17% in the last six months alone. This volatility directly impacts copper tracer wire prices, creating significant budgeting challenges for contractors working on large, long-term projects. Prices for CCS tracer wire, by comparison, are very stable.

Lower costs. CCS tracer wire is typically a more cost-effective option than solid copper. In some cases, CCS can cost 30-50% less than its copper counterpart — significant savings, especially for large infrastructure projects.

Lower weight. CCS is lighter than copper tracer wire by approximately 10%, which can reduce handling and shipping fees. There’s an advantage in the field as well. 10% may not seem significant, but for a tech carrying a 2,500-foot reel on a large job site, that weight difference can mean faster progress that translates into lower labor costs.

Kris-Tech manufactures CCS tracer wire in four strengths to address virtually any project requirement. Dead soft annealed (DSA) has similar characteristics to its solid copper counterpart, while stress relieved (SR) CCS provides greater durability and pulling strength. High strength (HS) and extra high strength (EHS) CCS tracer wire, our strongest CCS products, are used in the most demanding conditions. EHS tracer wire can withstand over 1,000 pounds of pulling pressure and is often used in blasting environments.

We also manufacture our CCS tracer wire in multiple gauges, a wide range of colors, and available customized print legends and packaging. Kris-Tech also offers non-standard lengths, smaller minimum runs, and no cut or reel charges.

Customers can be assured our copper clad steel tracer wire will perform safely and consistently to all specifications. Our Kris-Tech CCS tracer wire is extensively performance-tested and meets all applicable industry standards, including ASTM, NEMA, UL, and ICEA. All products are also spark tested at 7500.

Builders and contractors are looking for any advantage to meet challenging project timelines and tight budgets. In many cases, copper clad steel tracer wire can deliver an edge in performance — and cost savings.

Contact us to learn more about Kris-Tech’s Copper Clad Steel Tracer Wire

Subscribe to the Kris-Tech Blog