Tray cable is an amazingly versatile cable that works in many different environments.

An absolute all-star in the world of wire, tray cable seemingly does it all. It’s approved for use in wet and dry locations, is direct burial approved, and is sunlight resistant. The cable is functional across a wide swath of temperatures and can be made flame retardant for use in more dangerous locations. Whether you’re running it through indoor tray wireways or installing it in free air outside, tray cable is used across many commercial, manufacturing, and industrial applications.

Tray cable comes in many different styles, featuring a variety of layouts, insulations, jackets, shields, and even colors. While figuring out what color your conductors are may not seem like a big deal, understanding the codes and color schemes associated with them will help dictate its use and whether it’s NEC compliant.

Based on the color combinations you see, you’ll be able to determine what the wire is being used for.

If you were to cut a cross-section of Kris-Tech wire and look at it head-on, you’d see a series of colored conductors arranged in a circle around the main conductor. Depending on which end of the cable you’re looking at, you can read the colors clockwise or counterclockwise from the center black conductor.

Let’s say you cut your cable and see this series of colors: black, white, red, green, orange, and blue, in that order and in a consistent pattern. This is an E-1 color code (formerly known as a K-1 code) because it includes both a white and green conductor. As a result, this tray cable may not work for every situation. Per NEC guidelines, white is meant to serve as the neutral conductor, while green is only used to ground electrical equipment.

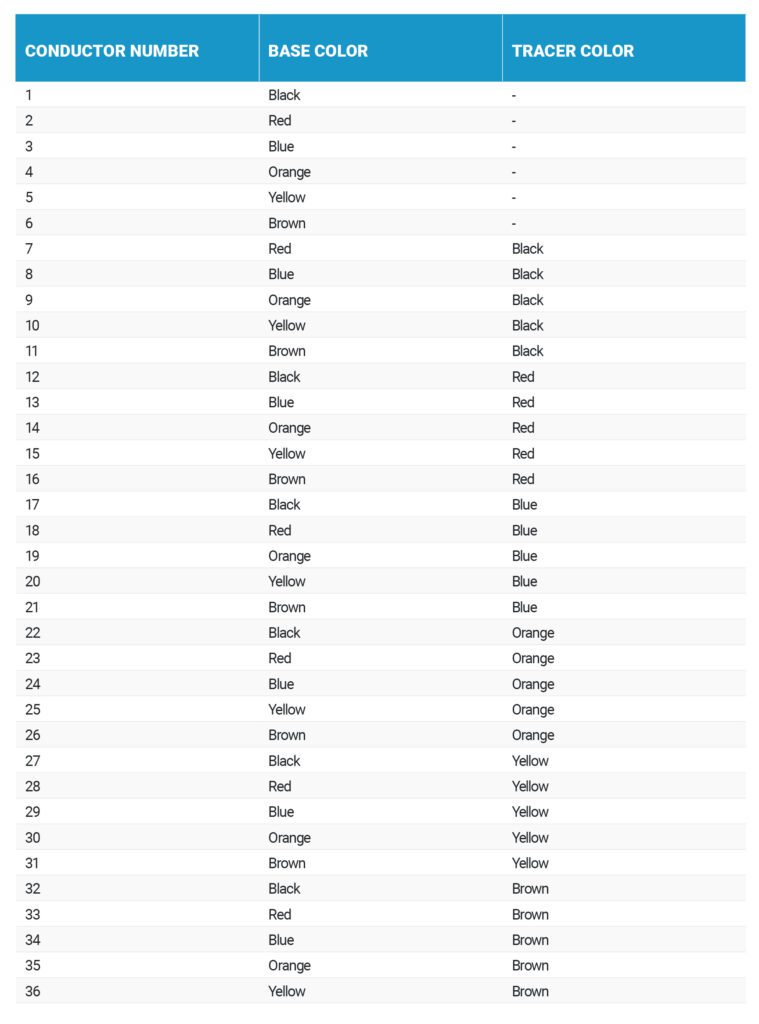

To account for this issue, another color code known as E-2 (formerly K-2) was developed, leaving out the white and green conductors. If you were to look at this cable head-on, you would see the colors arranged in the order of black, red, blue, orange, yellow, and brown.

E-2 color-coded wire fits NEC applications because it lacks white and green conductors. However, those colors can be added back in if they’re needed for the job, but they can only appear once in the cabling.

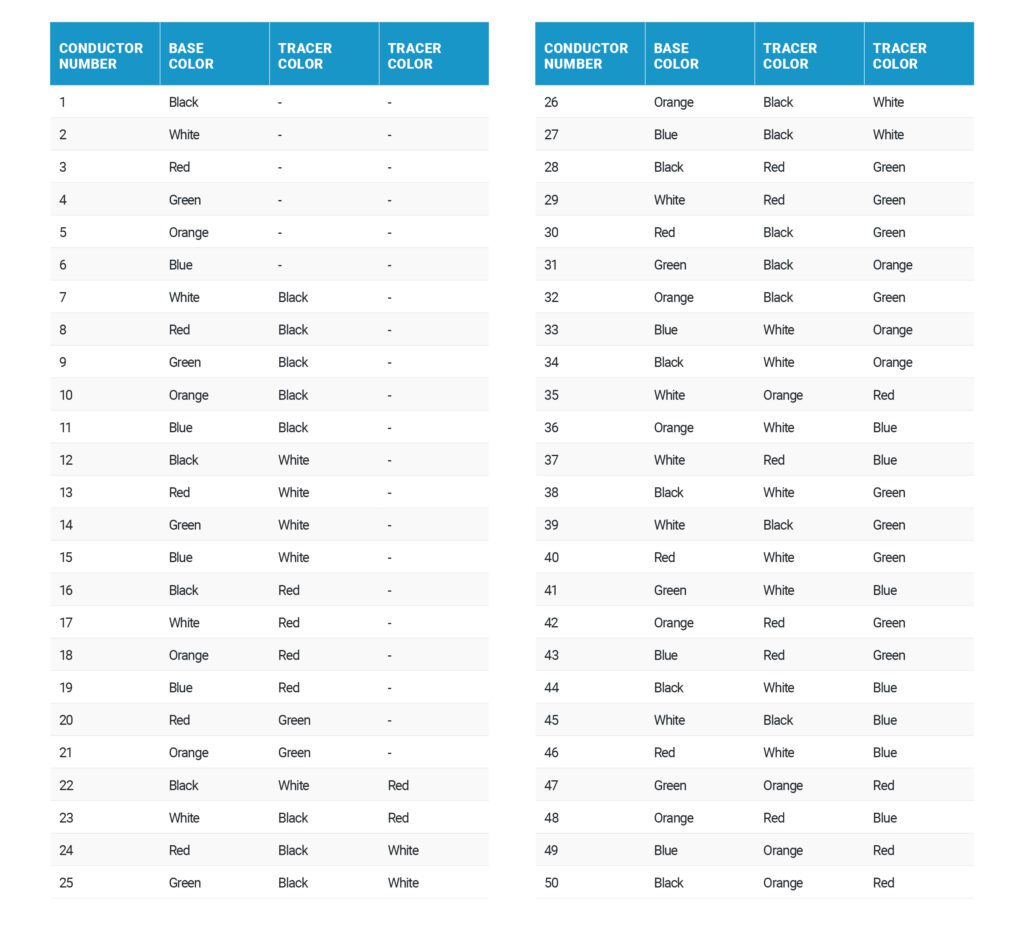

To further complicate things, as you add more conductors to your tray cable, manufacturers like Kris-Tech will add a tracer color to the conductors. The tracer color will be the same as the six used in the initial series but will not be applied to a conductor of the same color. For example, a black tracer color will not be added to a black conductor but will be for white, red, green, orange, and blue.

In yet another application of the color code, we end up with M-4. Tray cable with this color code avoids using colors altogether, opting for all black. Despite the monochromatic layout, each conductor is numbered to make it easier to identify which conductor is which.

Knowing when to use which color code can help you save time and prevent mistakes from occurring on the job.

You’ll likely need to use a tray cable with the E-1 color code if you’re working on an electrical or utility application. When the project is not NEC-applicable, E-1 is OK to use. Locations where you’ll likely encounter this color scheme include cogeneration plants, wastewater treatment plants, and other utilities.

More common out in the field are tray cables with the E-2 color code, which are used across many different heavy-duty applications. If NEC rules are applicable, like in commercial and industrial spaces, E-2 is the preferred choice for power and control cable. This is because the jobs this tray cable is used for typically require electrical appliances to be grounded – that means they need a ground wire.

You can typically find E-2 coded tray cable used across windmill applications, pulp and paper, mining operations, and the petrochemical industry.

No matter the job type, rest assured there’s a tray cable engineered to fit the job.

Kris-Tech is ready for your next job with UL 1277 certified vinyl nylon tray cable (VNTC) and cross-linked polyethylene tray cable (XPTC). Whether you need some tray cable color-coded to meet NEC guidelines or want it custom-colored to match your preferences, Kris-Tech can get the job done.

If you have questions, fill out a contact form letting us know what you’re looking for. We’ll be able to help you get the wire you need as quickly as possible.