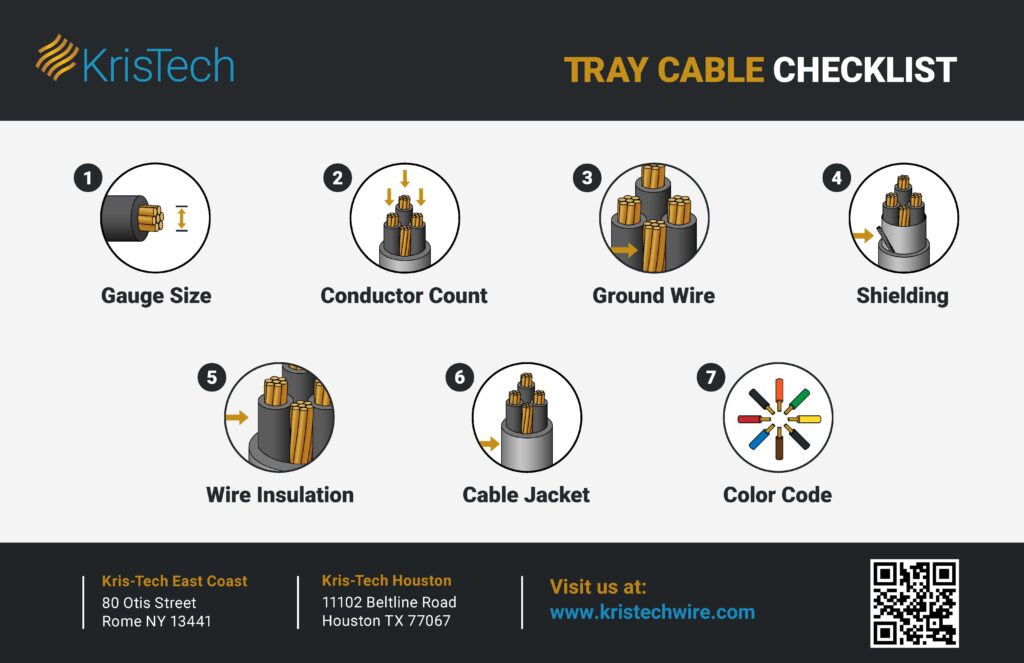

Tray cable comes in many different forms, each with its own shielding, cable jacketing, and insulation.

Long story short, customization is the name of the game for tray cable. Its mix-and-match design makes it a versatile choice for many projects, including industrial, commercial, and residential applications. From lighting and power to controls and signaling, seemingly no job is too much for tray cable to handle.

But sometimes, having a lot of custom options can make it difficult to figure out exactly what you need for the job. Though tray cable is a multi-purpose product, some combinations perform better in certain environments than others.

This handy guide highlights a few of the most common cables on the market and where you’re most likely to see them.

Note: All Kris-Tech tray cable is UL 1277 compliant, direct burial rates, exposed run (-ER) rated, and follows National Electrical Code (NEC) 9.2 and 9.3 standards.

XPTC or XLPE tray cable has cross-linked polyethylene (XLPE) insulated conductors jacketed with PVC for excellent corrosion resistance. Typically, you’ll see XPTC tray cable used for power and control cables in wet and dry locations. Like most tray cables, it performs well in cable trays, raceways, and in the open air.

Because of its insulation and jacketing, XPTC is weather and exposure resistant and direct burial rated. The cable also works well in Class 1, Division 2 locations where it could encounter chemicals.

Our XPTC cable standards include:

XHHW tray cable has a thermoset insulation made of XLPE, giving it high heat and water resistance (HH = high heat and W = water). Why does high heat resistance matter? This type of tray cable deforms less in high heat and overcurrent situations, reducing short circuit and fire risks.

This tray cable is also chemical and abrasion resistant, helping it excel in many harsh environments, including:

Like the other tray cables in this group, XLP has a cross-linked polyethylene (XLP) insulation. It also has a PVC outer jacket for corrosion protection and durability in high-demand applications.

XLP insulation is extremely durable and resistant to cracking and damage. It also provides good protection against ozone, solvents, and soldering, unlike low- or high-density polyethylene (HDPE). The 600-volt tray cable works well in conduit, cable tray, or direct burial applications, and is available in multi-conductor, multi-pair, and grounded configurations.

XPTC tray cable excels in harsh areas, wet or dry locations, and in Class 1, Division 2 hazard areas. You can find this cable in locations where contact with chemicals, moisture, or fire hazards is possible.

Common applications include:

VNTC tray cable has dual-rated THHN/TFFN conductors protected by a PVC outer jacket and designed for use in cable trays. It comes in many gauge sizes and is suitable for direct burial and Class 1 and 2, Division 2 locations. You can also find VNTC cable used in ducts, wireways, troughs and trays, and even in air – but only if supported by a messenger.

Generally, VNTC is a cost-effective cable, making it a practical choice for many commercial and light industrial projects.

Kris-Tech’s VNTC cable meets several standards, including:

Compared to XHHW, VNTC/THHN cable is less resistant to heat and moisture, making it more prone to attack by ants and rodents. The cable also has a thermoplastic insulation that can suffer damage in high heat conditions.

Like other tray cable products, THHN tray cable has a variety of gauge and conductor options. One of the most popular options available is the 4-3C THHN-PVC tray cable with ground, also known as a multi-conductor THHN cable. The cable works in temperatures up to 90°C in dry conditions and 75°C in wet ones, and provides outstanding sunlight, cold bend, and cold impact resistance.

Some applications include:

Also known as PLTC, these cables are durable and used in applications with power-limited circuits, like alarm systems.

Power limited tray cable works well across a wide temperature range with conductor operating temperatures up to 105°C. The cable is also sunlight resistant, suitable for wet and dry environments, and usable in Class I and II, Division 2 hazardous locations. Additionally, UL 13 tests the safety of PLTC cables used for low-voltage power and control.

Common PLTC applications include:

Wind Turbine Tray Cable, as the name implies, connects wind turbine generators to switchgears.

Since wind turbines are often subject to harsh weather and conditions, the cable used to connect them must be tough. WTTC has a high-performance insulation and jacket that resists oil and excels in cold temperatures.

These cables can also withstand the effects of:

Workers can install WTTC in cable trays or in raceways within turbine generators and other tight spaces. With its optional shielding, the cable has improved flexibility for installation in areas with limited space.

XLP-CPE tray cable has annealed copper conductors insulated with XLPE and jacketed with cross-linked Chlorinated Polyethylene (XL-CPE). The conductors can also be made using tinned copper.

The result is a flame-retardant cable with a direct burial rating you can install inside or outside. Workers like this cable because its insulation and jacketing prevent current leakage while protecting conductors from moisture and abrasion damage. You can also add shielding and a drain wire for added protection.

XLP-CPE is a power and control tray cable, making it a good fit for lighting, relays, and controls. Like other tray cables, XLP-CPE meets UL 1277 standards, passes the VW-1 Flame test, and is approved for Class 1, Division 2 hazardous locations.

Low smoke, zero halogen cables are relatively new to the market, but have grown in popularity.

These cables are common in public spaces because they don’t produce much, if any, smoke when they burn. LSZH cables also don’t expel as many toxic chemicals when they burn because they don’t use halogen material.

As a result, low smoke and halogen free cables are common in areas where people are. Typical applications include hospitals, entertainment venues, and mass transit locations, like airports and subway stations. LSZH is also worth consideration in tight spaces packed with other wires and cables.

To earn the LSZH designation, cables need to pass several tests, including the UL 1685 Vertical Flame Test, which is standard smoke release test for electrical and optical-fiber cables. Beyond being flame retardant, the cables provide excellent protection from crushing and impacts, moisture, chemicals, sunlight, and weather.

Because of these qualities, LSZH cable is good in wet or dry conditions, hazardous areas, and tight spaces.

Click here to view our downloadable tray cable spec sheets