Knowing the right wire for your project is essential. Knowing the right questions to ask will get you the wire and cable you need to kickstart your project. Kris-Tech’s John Olguin (Southwest Regional Inside Sales) shares his insights into the 6 elements to look out for when looking for the right tray cable for your project.

Tray cable comes in a variety of sizes. It is typical for a product to be listed with numbers representing gauge sizes; for example, VNTC Tray Cable 12-2 AWG or XPTC Tray Cable 14-10 AWG. The first number such as 12 or 14, specifies the gauge while the second #2 or 10 represents the number of current-carrying conductors. The wire can also have an extra ground number. VNTC Tray Cable 12-2 AWG would therefore mean a tray cable with 12-gauge, 2 insulated current carrying wires, plus a ground.

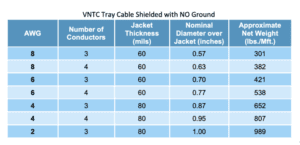

Here is an example of a VNTC tray cable spec sheet containing AWG sizes.

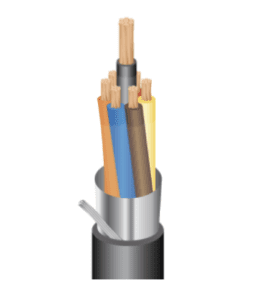

A cable that is shielded contains insulated conductors encased in a standard conductive layer. Shielded tray cables are normally more rigid and thicker compared to unshielded ones. Unlike unshielded cables, shielded cables require greater care when working with them. Shielded cables are often found in industrial settings where other equipment is likely to generate interference.

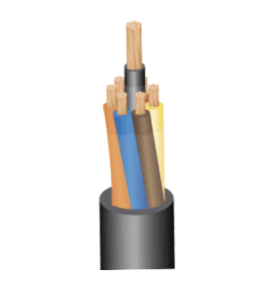

ii) Unshielded VNTC tray cable

Conductor count is the number of insulated conductors in a cable. For instance, a red, black, white and bare ground is a three conductor and a red, black, white and green is a four conductor.

In a product description such as VNTC Tray Cable 12-2 AWG, the second number refers to the number of current-carrying conductors in the wire I.e. the conductor count.

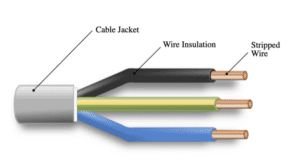

A cable or wire is insulated to prevent the wire’s current from coming into contact with other conductors. Normally the insulated wire or cable would consist of a non-conductive material that is resistant to electric current.

Typical insulation materials for tray cable include:

A VNTC Tray cable uses a THHN insulation while the XPTC tray cable uses an XLP insulation. XPTC’s XLP insulation is more durable compared to VNTC.

A wire or cable jacket is used to offer protection from moisture, flame, chemical, and UV damage. It also protects the cable or wire from damage during and after the installation process. As the cable’s outermost layer, a jacket is the first line of mechanical defense for its inner components, providing protection for the shielding and conductors within the cable. Different materials can be used as jackets.

Typical jacket materials include:

Color coding is one of the many identification standards used for wires. It is used to establish a standard for use by different manufacturers. Different color codes are used to identify conductors for point-to-point wiring and for circuit diagrams. However, not all wire color codes are the same. They differ based on several factors including but not limited to installation type, location, and voltage. For example, phase 2 of the 120 Volt AC wire is color coded as Red in the United States but Black in Europe. Some color codes are specified by law but not always as others are based on common practice.

Here is an example of how a wire jacket can communicate its predetermined use to an electrician.

Author: John Olguin

John Olguin is the Southwest Regional Inside Sales at Kris-Tech, a copper wire manufacturing company headquartered in Rome, New York.

Subscribe to the Kris-Tech Blog