If you’ve ever worked with tracer wire, you likely know how difficult the environments can be.

Tracer wire needs to be ready for anything, from sharp rocks and moisture to chemicals and fluctuating temperatures. That means manufacturers need top-notch insulation to prevent damage to the copper conductors hidden inside.

Tracer wire products typically feature a high molecular weight polyethylene (HMWPE) insulation, but under that umbrella there are several options.

The two most commonly used tracer wire insulations are members of the HMWPE family – high density polyethylene (HDPE) and linear low density polyethylene (LLDPE). But one size doesn’t fit all; knowing which type of polyethylene insulation works best depends on several factors, including:

Application: What and where is the wire used for? Depending on the job, it makes more sense to choose one option over another.

Installation Method: Open-cut and trench projects are less harsh than heavy-duty ones like directional drilling and pipe bursting.

Soil Conditions and Environment: Every environment is different, requiring crews to analyze the conditions. Is the soil rocky, clay, or soft? Are workers installing tracer wire in a wet environment? Is there a threat of chemical exposure that could damage conductors?

Though HDPE and LLDPE are both high molecular weight polyolefin hydrocarbons, minor differences impact performance.

This is because of differences in their molecular structures that affect several aspects of the insulation, like:

HDPE and LLDPE have strengths and weaknesses, but each excels in certain applications. Knowing the difference could save you money, time, and headaches in the long run.

HDPE is a direct burial rated wire insulation known for its rigidity, strength, and “slippery” feel.

Because of its strength, HDPE is suitable for jobs where durability and abrasion resistance are important, including directional drilling, plowing, and pipe bursting. It also excels in locations where chemical contact is possible.

So, what makes high density polyethylene so strong? It all comes down to its tight molecular structure.

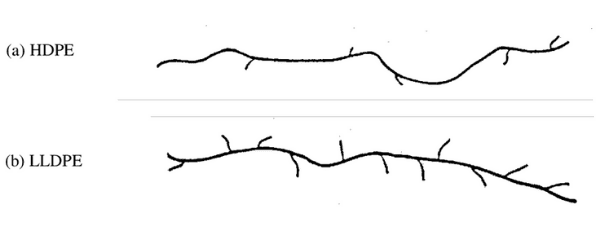

HDPE features a sturdy linear structure with minimal branching. This creates a dense, durable, chemical-resistant material with a high melting point. The thermoplastic insulation is suited for harsh environments calling for top-notch protection or high operating temperatures.

Strength and durability aren’t everything, and sometimes being rigid is an issue.

HDPE’s bonds give the insulation a stiff structure, which doesn’t make it easy for workers to bend. It also doesn’t have as much stretch as other insulation options, because of elongation. Other potential concerns include its lack of UV resistance, though additives can give HDPE that property.

Finally, though HDPE has a higher tensile strength and break load, it can struggle under high pressure.

Thanks to its molecular structure, HDPE makes sense for straight-line projects and long runs. Unfortunately, it performs less well in tight installations or jobs with bends.

Although not a weakness, HDPE insulation is generally more expensive than LLDPE, because HDPE is a virgin compound.

Linear low density polyethylene (LLDPE) has a similar molecular structure to HDPE, giving it many of the same attributes. Where it differs, though, is in its branching structure.

LLDPE has the same type of linear chain at its core, but many more branches. These branches keep the molecules pressed less tightly together than HDPE, giving it more flexibility. The result is less dense, more bendable insulation.

Because the insulation is more malleable and easier to bend, it’s less likely to break if an accident occurs. Workers also like using it for open-cut and trench projects because it’s easier to install in tight spaces.

Like HDPE, standard LLDPE is not UV resistant, though additives can give it the property. It also has a high melting point, performs well in cold environments, offers puncture resistance, and is less brittle than HDPE.

Although it has a similar structure to other HMWPE materials, LLDPE’s mechanical properties differ slightly from HDPE.

LLDPE is a resilient material and great tracer wire insulation but doesn’t offer the same abrasion protection as HDPE. The insulation may not perform as well in rocky locations or where the wire is subject to crushing.

With that said, LLDPE is perfect for open-cut and trench applications. It also does well in tight areas and for projects where flexibility is crucial.

Medium density polyethylene (MDPE) is not as common as the other insulations mentioned, but has several positive attributes.

Like HDPE and LLDPE, MDPE has a strong main linear chain with molecular branches. However, it has more molecular branches than HDPE and fewer than LLDPE. The result is a flexible, strong, chemical-resistant insulation with features of both its counterparts.

MDPE is not a standard KrisTech insulation offering but can be requested.

No matter what insulation you choose, rest assured your tracer wire will withstand the tests of time.

HDPE and LLDPE are great insulations but excel in different conditions. Thanks to its tight molecular bond, HDPE is durable, rigid, and chemical resistant, and performs across a wide temperature range. HDPE insulation is up for the challenge, whether directional drilling, plowing, micro tunneling, or pipe bursting.

Meanwhile, LLDPE insulation has greater flexibility, allowing crews to install wire in tighter spots with less trouble. The material is chemical resistant, tough, and works across many temperatures. Common applications include open trench projects and tight areas where bending is necessary.

Finally, if cost is a factor, HDPE is more expensive than LLDPE. This is because HDPE is a virgin compound, unlike LLDPE, which has an unconventional structure.

Safety is the number one priority on every worksite. If you have questions or need more information, KrisTech can help.

And remember, buying tracer wire is about more than finding the best price. Understanding how the insulations work, where they perform best, and what their strengths and weaknesses are goes a long way.

With the right information, projects can be safer, more reliable, cost-effective, and perform for decades.