If you’ve ever taken a driver’s ed class, you probably remember learning about road signs and signals.

Wheeling a multi-ton hunk of metal at 65 mph is daunting; simultaneously processing data makes it harder. Thankfully, road signs are great, fast communicators that keep people safe, point them in the right direction, and warn of potential danger ahead.

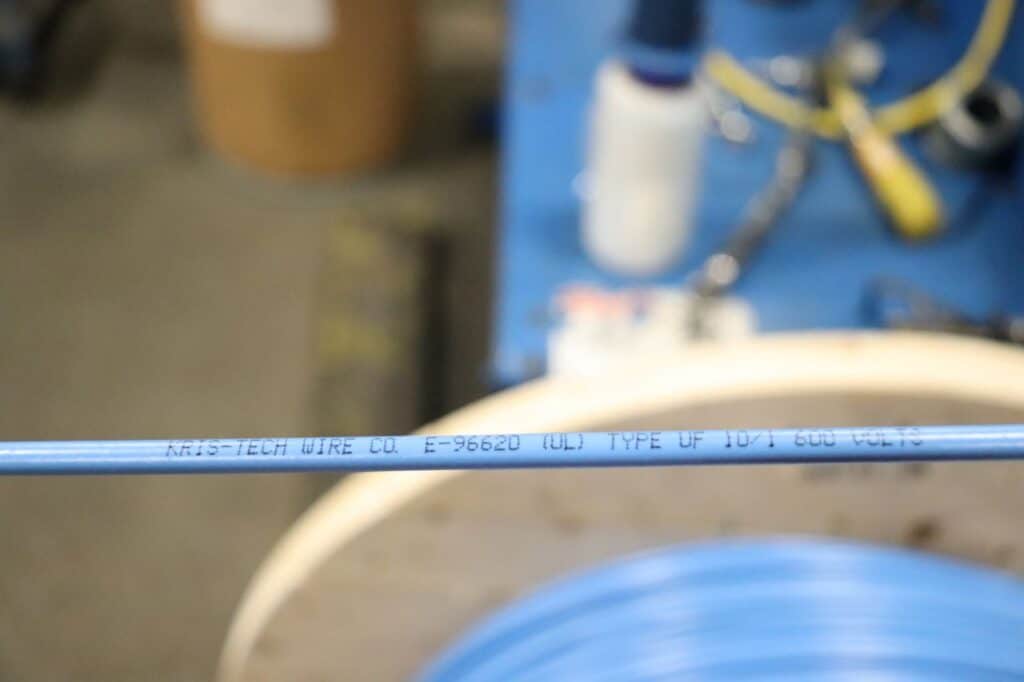

For wire and cable products, we have our own version of road signs printed directly on the wire we use. Using only a few letters and numbers, electrical workers get all the info they need. With a quick glance, it’s easy to see what type of wire they’re working with, its size, material, and other attributes. And much like the different colors we see on road signs, different hues designate specific applications.

But how do we go about speaking the language?

When you order wire or cable from KrisTech, our wire legends generally follow Underwriters Laboratories guidelines.

Depending on the product you order, the requirements may vary based on the UL spec. However, print wheels often follow the same general information criteria unless the project needs a custom legend.

Let’s look at an example of a printed wire legend that you might find on a length of XHHW-2 wire:

KRISTECH WIRE CO. #XX AWG (XX MM2) XLP TYPE XHHW-2 600V AND 1000V OR RW90 600V 90C (-40C) WET OR DRY C(UL)US

What might seem like a mishmash of words and numbers is actually a critical roadmap for electrical workers. Within a few seconds, employees have all the information they need to determine what they’re working with.

Starting from the beginning, the example print wheel features several data points, including:

Manufacturer’s ID (KRISTECH WIRE CO or KT): This information will change depending on which company produced the wire.

Conductor Size (#XX AWG): This information is sometimes shown in both AWG and mm². Cable products differ slightly because there are multiple conductors. Legends may show numbers like 12-2 or 14-3, meaning there are two 12 AWG conductors or three 14 AWG conductors, respectively.

Wire Type Designation (TYPE XHHW-2): Wire type is most often displayed using a series of letters. Each letter means something different; if you’re unfamiliar with the meanings, we break everything down for you here. You can also find this information in the National Electrical Code (NFPA 70).

Voltage Marking (600V, 1000V, 2000V, etc.): This one is pretty self-explanatory. It determines the wire’s maximum safe operation voltage. Exceeding this amount could cause damage, including overheating, melting, shocks, and fire risks.

Occasionally, products may have two different voltage ratings, depending on whether they can be used as different wire types (ex. XHHW-2 600V or RW90 600V). Multiple ratings could also apply to the application. For example, XHHW-2 carries a 600V rating for phase-to-ground, while 1000V is for phase-to-phase.

Dry and Wet Temperature Ratings (90°C (-40°C) WET OR DRY): The highest ambient temperature the wire safely operates at. Another way to determine operating temperature is by looking for a “-2” in the wire type, which means the same thing.

Conductor stranding (7 STR, 37 STR, etc.): This determines the number of strands the conductor has.

Conductor material (AL, CU, TINNED, etc.): What is the conductor made of? This could be copper, aluminum, or tinned copper, among others.

While the above data is common, manufacturers might print other information on the wire’s insulation or jacketing, like:

UL isn’t the only safety organization workers may come across while examining wire. The CSA, IEC, and other regional groups each have their own guidelines that manufacturers must follow.

Lastly, depending on the customer’s needs, manufacturers can print the sequential footage along the length of the wire. This number helps workers determine how much product is on the reel or spool.

Similar to road signs, wire type may impact insulation and jacket colors.

For example, tracer wire insulation colors follow APWA guidelines. Each color signifies a specific utility type, helping workers quickly identify underground assets.

Tray cable follows several color codes associated with ICEA S-73-532. Depending on the application and the industry, jobs may require E-1, E-2, M-4, or a custom color code.

Sometimes, wire colors dictate their use. For example, manufacturers use green insulation for grounding wire, though bare copper wire is also an option.

In residential systems, black or red insulation marks hot wires, while white or gray ones denote neutral wires. For low-voltage installations, blue or yellow insulation may mark hot wires used in a three-phase electrical system.

Most electrical wires look the same at first glance, but print wheels offer valuable clues to make sense of what they are and how they’re used.

Without the markings, workers risk using the wrong wire for their projects. Over time, it can become damaged, possibly leading to fires, shock risks, and arcing. At best, the wire may not perform as well as expected.

So, keep a vigilant eye and remember your wire legend rules to protect yourself and others.