Tray cables are multi-purpose wires used across many industries. Applications include industrial power, lighting, control, instrumentation and signal circuits, and switching. It can be installed in conduits, ducts, raceways, and cable tray systems, is direct burial rated, and has indoor and outdoor uses. Cables marked with TC-ER can be used between cable trays and equipment or devices.

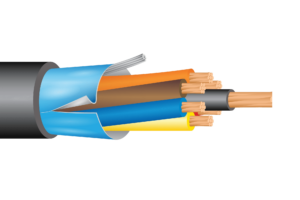

Single conductors are solid or stranded and annealed or hardened uncoated copper. Tinned conductors and other stranded configurations are available upon request.

Single conductors are insulated with a concentrically applied XLPE (crosslinked polyethylene) insulation that is VW-1 flame and “Oil and Gasoline Resistant I” rated.

All black insulation is rated “Sunlight Resistant.” All colored insulation is rated “Sunlight Resistant” in sizes #6 AWG and larger, and optional in sizes #8 AWG and smaller.

The assembly is lined with an optional tinned copper drain wire and then wrapped with an Aluminum-Mylar shielding.

The assembly is jacketed with a concentrically applied PVC jacket. Overall cable profile will be similar to the interior conductor assembly layout.

Print legends on the wire include the manufacturer, conductor size, voltage rating, UL symbol (if applicable) and type designation. Standard length spools are 500 or 2500 feet.

| AWG | Number of Conductors | Jacket Thickness (Mils) | Nominal Diameter over Jacket (Inches) | Approx. Net Weight (Lbs/1000') |

|---|---|---|---|---|

| 14 | 2 | 45 | 0.36 | 59 |

| 14 | 3 | 45 | 0.38 | 78 |

| 14 | 4 | 45 | 0.41 | 98 |

| 14 | 5 | 45 | 0.45 | 119 |

| 14 | 6 | 45 | 0.49 | 139 |

| 14 | 7 | 45 | 0.49 | 156 |

| 14 | 9 | 45 | 0.63 | 216 |

| 14 | 10 | 60 | 0.65 | 236 |

| 14 | 12 | 60 | 0.68 | 272 |

| 14 | 13 | 60 | 0.71 | 293 |

| 14 | 16 | 60 | 0.75 | 349 |

| 14 | 19 | 60 | 0.79 | 404 |

| 14 | 25 | 80 | 0.96 | 555 |

| 14 | 30 | 80 | 1.02 | 649 |

| 14 | 42 | 80 | 1.18 | 879 |

| AWG | Number of Conductors | Jacket Thickness (Mils) | Nominal Diameter over Jacket (Inches) | Approx. Net Weight (Lbs/1000') |

|---|---|---|---|---|

| 12 | 2 | 45 | 0.40 | 79 |

| 12 | 3 | 45 | 0.42 | 107 |

| 12 | 4 | 45 | 0.46 | 137 |

| 12 | 5 | 45 | 0.50 | 165 |

| 12 | 6 | 60 | 0.58 | 209 |

| 12 | 7 | 60 | 0.58 | 235 |

| 12 | 9 | 60 | 0.70 | 298 |

| 12 | 10 | 60 | 0.73 | 328 |

| 12 | 12 | 60 | 0.75 | 382 |

| 12 | 16 | 80 | 0.88 | 523 |

| 12 | 18 | 80 | 0.92 | 581 |

| 12 | 19 | 80 | 0.92 | 607 |

| 12 | 25 | 80 | 1.08 | 782 |

| AWG | Number of Conductors | Jacket Thickness (mils) | Nominal Diameter over Jacket (inches) | Approx. Net Weight (Lbs/Mft) |

|---|---|---|---|---|

| 10 | 2 | 45 | 0.44 | 110 |

| 10 | 3 | 45 | 0.47 | 151 |

| 10 | 4 | 45 | 0.52 | 194 |

| 10 | 5 | 60 | 0.59 | 252 |

| 10 | 6 | 60 | 0.65 | 298 |

| 10 | 7 | 60 | 0.65 | 337 |

| 10 | 8 | 60 | 0.73 | 384 |

| 10 | 9 | 60 | 0.79 | 430 |

| 10 | 10 | 80 | 0.87 | 503 |

| 10 | 12 | 80 | 0.90 | 585 |

| 10 | 16 | 80 | 0.99 | 755 |